Metalworking precision innovations have transformed the construction of stadiums, creating architectural marvels that capture the imagination. The tales behind these remarkable structures are as captivating as the metalworking craftsmanship that brings them to life.

From the intricate design process to the final meticulous touches, each step showcases the immense skill and expertise of metalworkers. By pushing the boundaries of what is possible, these artisans have crafted stadiums that not only serve as sports venues but also stand as symbols of human ingenuity and creativity.

In this article, we will delve into the fascinating stories behind stadiums crafted with metalworking precision, uncovering the secrets and mysteries that have made them legendary. Get ready to be enthralled by the fusion of art and engineering that elevates these structures to iconic status.

Key Takeaways

- Metalworking techniques have evolved throughout history, from ancient civilizations to modern times.

- Advanced technologies like CAD and CNC have revolutionized metalworking precision.

- Metalworking plays a crucial role in the construction of stadiums, from creating structural components to incorporating architectural features.

- Metalworking precision has revolutionized stadium design, enabling the creation of iconic and visionary structures.

The Evolution of Metalworking Precision

The Evolution of Metalworking Precision has been a remarkable journey marked by continuous innovation and advancements in techniques and technology. From the earliest civilizations to modern times, metalworking has played a crucial role in shaping our world. The ancient Egyptians, for example, used copper to create intricate jewelry and decorative objects, showcasing their mastery of the craft. Over time, metalworking techniques evolved, and new materials such as bronze and iron were introduced, allowing for the creation of more durable and versatile products.

In the medieval period, metalworking precision took a significant leap forward with the development of new tools and techniques. Blacksmiths honed their skills and became adept at forging intricate designs, such as armor and weapons. This period also saw the emergence of guilds, which ensured quality control and the transfer of knowledge from one generation to the next.

The industrial revolution of the 18th and 19th centuries brought about a revolution in metalworking precision. With the advent of steam power and the use of machinery, mass production became possible, leading to the creation of complex structures and machinery on a scale never before seen.

Today, metalworking precision continues to evolve at a rapid pace. Advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) have revolutionized the industry, allowing for greater accuracy and efficiency in the manufacturing process. Materials such as titanium and carbon fiber have also been introduced, offering new possibilities in terms of strength and weight reduction.

Advancements in Metalworking Techniques

Advancements in metalworking techniques have revolutionized the industry, enabling greater precision, efficiency, and versatility in the manufacturing process. These innovations have paved the way for a new era in metalworking, where complex and intricate designs can be achieved with ease.

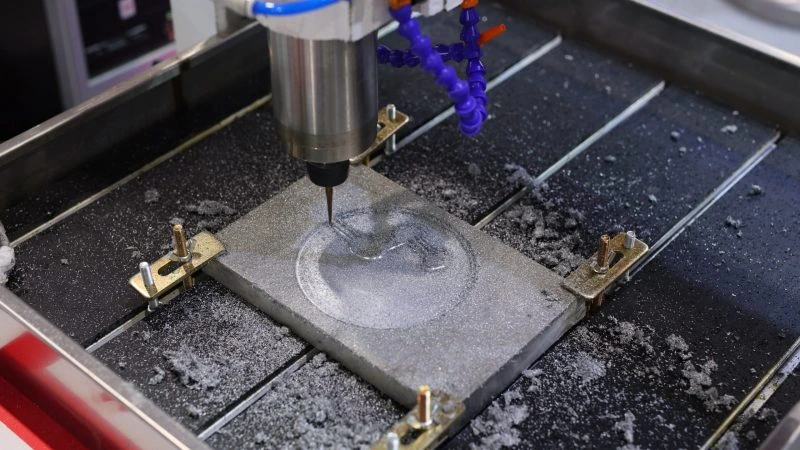

One noteworthy advancement is the use of computer numerical control (CNC) machines. These machines are equipped with sophisticated software that allows for precise control and manipulation of metalwork. With CNC machines, manufacturers can create intricate patterns and designs that were once deemed impossible. This level of precision ensures that every piece is crafted to perfection, resulting in high-quality products.

Another advancement is the development of laser cutting technology. Laser cutting provides a more efficient and accurate method of cutting metal, compared to traditional methods such as sawing or shearing. The laser beam can precisely follow a predetermined path, cutting through the metal with extreme precision. This technique eliminates the need for additional finishing processes, as the edges are clean and smooth.

In addition to precision, advancements in metalworking techniques have also led to increased efficiency. Automated processes and robotic systems have streamlined production, reducing the time and labor required to manufacture metal products. This not only improves productivity but also lowers costs, making metalworking more accessible to a wider range of industries.

Furthermore, these advancements have enhanced the versatility of metalworking. With new techniques and technologies, manufacturers can work with a wide variety of metals, including stainless steel, aluminum, and titanium. This allows for the creation of custom products that cater to specific requirements and design preferences.

The Role of Metalworking in Stadium Construction

With the advancements in metalworking techniques revolutionizing the industry, it is evident that metalworking plays a crucial role in the construction of stadiums. Metalworking precision is essential in creating the structural components that make up these iconic sporting venues. From the framework that supports the massive roofs to the intricate details of the seating arrangements, metalworking ensures that stadiums are not only visually appealing but also safe and functional.

One of the primary uses of metalworking in stadium construction is the fabrication of steel structures. Steel is known for its strength and durability, making it an ideal material for constructing stadium roofs, grandstands, and other large-scale components. Metalworking techniques such as welding, cutting, and bending are employed to shape and assemble these steel structures with precision. This ensures that the stadium can withstand various environmental factors, including strong winds and heavy loads.

Metalworking also plays a crucial role in the creation of architectural features in stadiums. Intricate metalwork designs are often incorporated into the facades, entrances, and signage of these venues, adding a touch of elegance and uniqueness. These metal elements are meticulously crafted using techniques such as laser cutting and CNC machining, resulting in intricate patterns and precise detailing.

Furthermore, metalworking is vital in the installation of seating systems in stadiums. The seats are typically mounted on metal frameworks, which are designed to provide comfort, stability, and ease of access for spectators. Metalworking techniques, such as forming and welding, are used to create these frameworks, ensuring that they meet the specific requirements of the stadium design.

Unveiling the Secrets of Metalworking Precision

Unveiling the intricacies of metalworking precision reveals the meticulous techniques and attention to detail required to craft stadiums with unparalleled accuracy. Metalworking precision is a key element in the construction of stadiums, ensuring that every component is fabricated to exact specifications. From the structural framework to the seating arrangements, metalworking precision plays a crucial role in creating a safe and visually appealing environment for spectators.

One of the secrets behind metalworking precision lies in the advanced technology and machinery used in the process. Computer-aided design (CAD) software allows engineers to create detailed 3D models of stadium components, enabling precise measurements and calculations. These models are then translated into instructions for computer numerical control (CNC) machines, which use automated cutting, bending, and welding techniques to shape the metal with unparalleled accuracy.

Attention to detail is another crucial aspect of metalworking precision. Skilled craftsmen meticulously inspect each piece, ensuring that it meets the required tolerances and quality standards. This level of scrutiny helps to eliminate any potential flaws or weaknesses that could compromise the structural integrity of the stadium.

In addition to precision, metalworking also offers flexibility in design. With the ability to bend, shape, and weld metal, architects and engineers can create unique and innovative structures that enhance the visual appeal of stadiums. Metalworking precision allows for the creation of intricate patterns, curved surfaces, and complex geometries, transforming stadiums into architectural marvels.

The Impact of Metalworking Innovations on Stadium Design

Metalworking precision has revolutionized stadium design by introducing innovative techniques and materials that push the boundaries of architectural possibilities. The impact of metalworking innovations on stadium design is undeniable, as it has enabled the creation of iconic structures that captivate audiences and bring communities together.

One of the key ways metalworking precision has influenced stadium design is through the use of advanced fabrication techniques. These techniques allow for the creation of intricate and complex metal structures that were previously not feasible. From the intricate latticework of the Beijing National Stadium, also known as the ‘Bird’s Nest,’ to the sleek curves of the Allianz Arena in Munich, metalworking precision has enabled architects to bring their visionary designs to life.

In addition to fabrication techniques, metalworking innovations have also introduced new materials that have transformed stadium design. Advanced alloys and composites offer enhanced strength, durability, and flexibility, allowing architects to create structures that can withstand the demands of large crowds and adverse weather conditions. These materials also provide opportunities for unique aesthetic expressions, as seen in the shimmering metallic facades of stadiums like the Mercedes-Benz Stadium in Atlanta.

Metalworking precision has not only revolutionized the design of stadiums but also the overall fan experience. With the ability to create intricate structures with precision, architects have been able to optimize sightlines, acoustics, and airflow within stadiums, ensuring an immersive and comfortable experience for spectators. Additionally, metalworking innovations have also enabled the incorporation of state-of-the-art technology, including retractable roofs and advanced lighting systems, further enhancing the overall atmosphere and functionality of stadiums.

Future Trends in Metalworking Precision

The future of metalworking precision holds great promise for advancing stadium design and pushing the boundaries of architectural innovation. As technology continues to evolve and improve, so too does the precision and efficiency of metalworking techniques. This opens up a world of possibilities for stadium construction, allowing designers and engineers to create structures that are not only visually stunning but also highly functional and sustainable.

One of the future trends in metalworking precision is the use of advanced materials. With the development of new alloys and composites, stadiums can be built with lighter, stronger, and more durable materials. This not only reduces construction costs but also allows for greater flexibility in design. For example, lightweight materials can be used to create intricate and complex structures that were not possible before.

Another trend is the integration of smart technology into stadium construction. This includes the use of sensors, automation, and data analytics to optimize performance and improve the fan experience. For instance, sensors can be embedded in the metal framework to monitor structural integrity in real-time, ensuring the safety of spectators. Automation can streamline the fabrication process, reducing errors and increasing efficiency. Data analytics can help stadium operators analyze crowd behavior and preferences, enabling them to provide personalized experiences for fans.

In addition, 3D printing is expected to play a significant role in the future of metalworking precision. This technology allows for the creation of complex shapes and structures with minimal waste, reducing costs and construction time. It also enables customization, allowing stadiums to be tailored to the specific needs and preferences of the teams and fans.

Frequently Asked Questions

What Are Some Examples of Stadiums That Have Been Crafted With Metalworking Precision?

Some examples of stadiums crafted with metalworking precision include the Mercedes-Benz Stadium in Atlanta, the Allianz Arena in Munich, and the Beijing National Stadium. These stadiums showcase the meticulous craftsmanship and technical expertise of metalworkers in creating architectural marvels.

How Has Metalworking Precision Evolved Over Time?

Metalworking precision has evolved over time through advancements in technology and techniques. From traditional handcrafting to computer-aided design and manufacturing (CAD/CAM), the industry has embraced automation and precision tools, resulting in greater accuracy and efficiency in the production of metal components.

What Are Some of the Latest Advancements in Metalworking Techniques?

Some of the latest advancements in metalworking techniques include the use of computer-aided design and manufacturing (CAD/CAM), 3D printing, and laser cutting. These innovations have improved precision, efficiency, and the ability to create complex and intricate metal designs.

How Does Metalworking Play a Role in the Construction of Stadiums?

Metalworking plays a crucial role in the construction of stadiums, providing the precision and structural integrity necessary for these iconic structures. From the fabrication of steel beams to the installation of architectural metalwork, it ensures the safety and durability of these monumental venues.

How Do Metalworking Innovations Impact the Design of Stadiums?

Metalworking innovations have a significant impact on stadium design. These advancements allow for the creation of intricate and precise metal structures, resulting in visually stunning and structurally sound stadiums that elevate the fan experience and contribute to the iconic status of these architectural marvels.

Conclusion

In conclusion, the use of metalworking precision in stadium construction has revolutionized the field of architecture and sports. Through cutting-edge techniques and state-of-the-art equipment, metalworkers have been able to create awe-inspiring structures that push the boundaries of design. The fusion of art and engineering in these stadiums leaves spectators in awe and enhances the overall fan experience. The future of metalworking precision holds promise for even more innovative and captivating stadium designs.

You May Also Like: